In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of

a product from inception,

through engineering design and manufacture, to service and disposal of manufactured products. PLM integrates people, data,

processes and business systems and provides a product information backbone for companies and their extended enterprise.

...

PLM systems help organizations in coping with the increasing complexity and engineering challenges of developing

new products for the global competitive markets.

...

Documented benefits of product lifecycle management include:

- Reduced time to market

- Improved product quality and reliability

- Reduced prototyping costs

- More accurate and timely request for quote generation

- Savings through the re-use of original data

- A framework for product optimization

- Reduced waste

- Savings through the complete integration of engineering workflows

- Documentation that can assist in proving compliance with directives and regulations

- Improved forecasting to reduce material costs

- Maximize supply chain collaboration

Areas of PLM

Within PLM there are five primary areas:

- Systems engineering (SE)

- Product and portfolio m˛ (PPM)

- Product design (CAx)

- Manufacturing process management (MPM)

- Product data management (PDM)

Introduction to development process

The core of PLM (product lifecycle management) is in the creation and central management of all product data and the

technology used to access this information and knowledge. PLM as a disci-pline emerged from tools such as CAD,

CAM and PDM, but can be viewed as the integration of these tools with methods, people and the processes through all

stages of a product’s life. It is not just about software technology but is also a business strategy.

Product lifecycle management

Phases of product lifecycle and corresponding technologies

...

- Conceive

- Specification

- Concept design

- Design

- Detailed design

- Validation and analysis (simulation)

- Tool design

- Realise

- Plan manufacturing

- Manufacture

- Build/Assemble

- Test (quality control)

- Service

- Sell and deliver

- Use

- Maintain and support

- Dispose

The major key point events are:

- Order

- Idea

- Kickoff(A kickoff meeting is the first meeting with the project team and the client of the project.)

- Design freeze ('design freeze' describes the end point of the design phase at which a technical product

description is handed over to production)

- Launch

...

Design is an iterative process, often designs need to be modified due to manufacturing constraints or conflicting requirements.

...

From all above mentioned phases of product lifecycle and coresponding technologies, only Design and Realize will be further detailed.

...

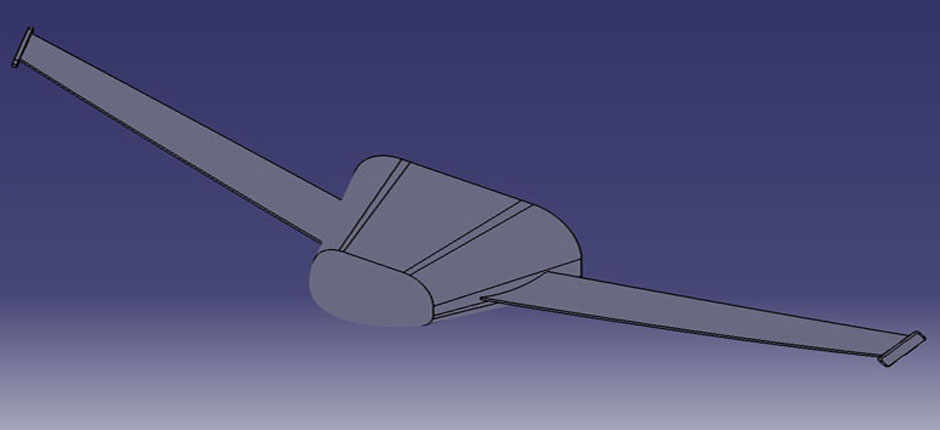

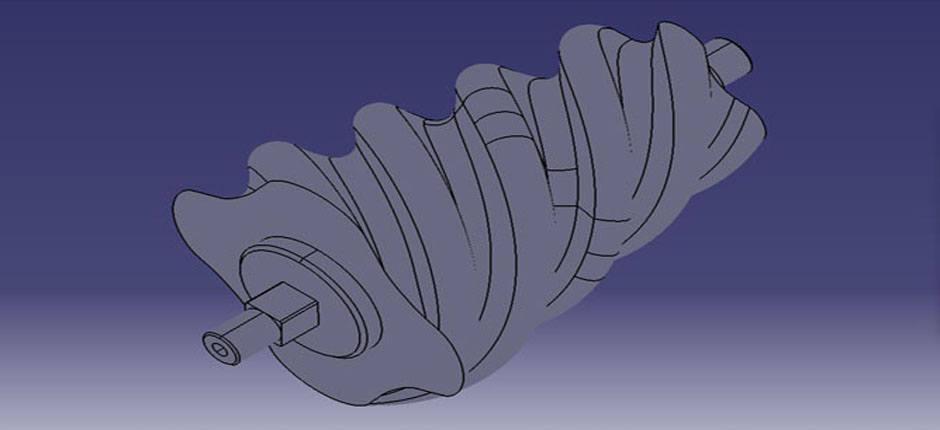

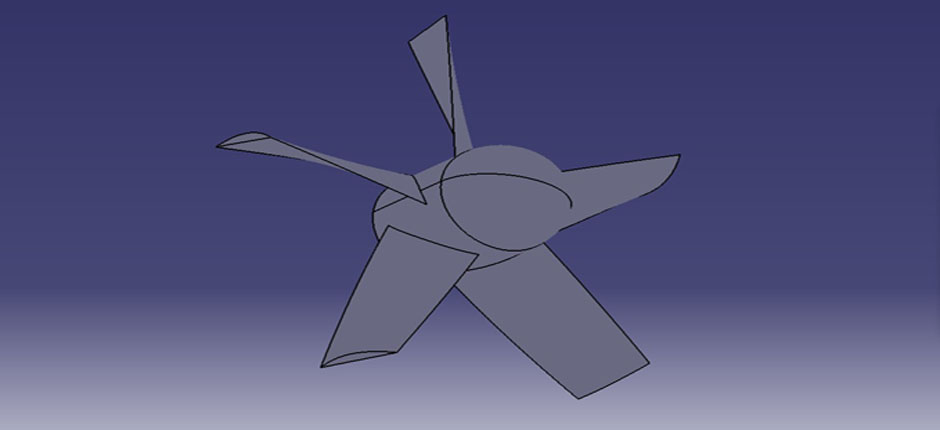

Design

Describe, define, develop, test, analyze and validate

This is where the detailed design and development of the product’s form starts, progressing to pro-totype testing,

through pilot release to full product launch. It can also involve redesign and ramp for improvement to existing products

as well as planned obsolescence. The main tool used for design and development is CAD.

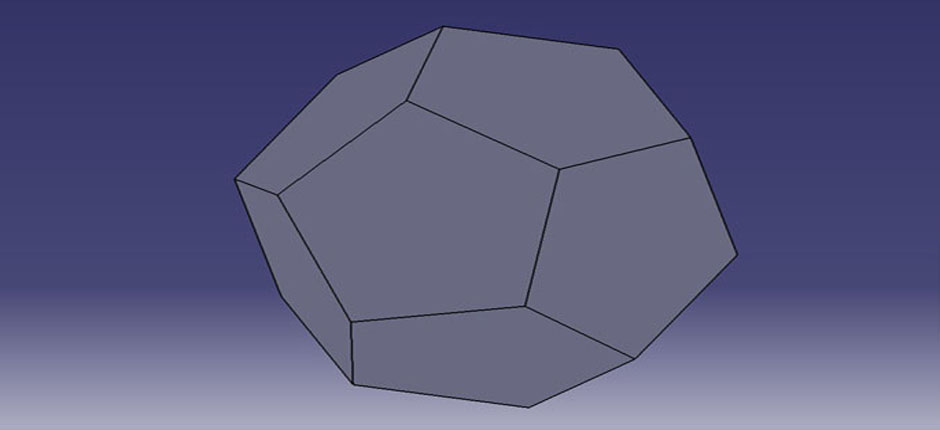

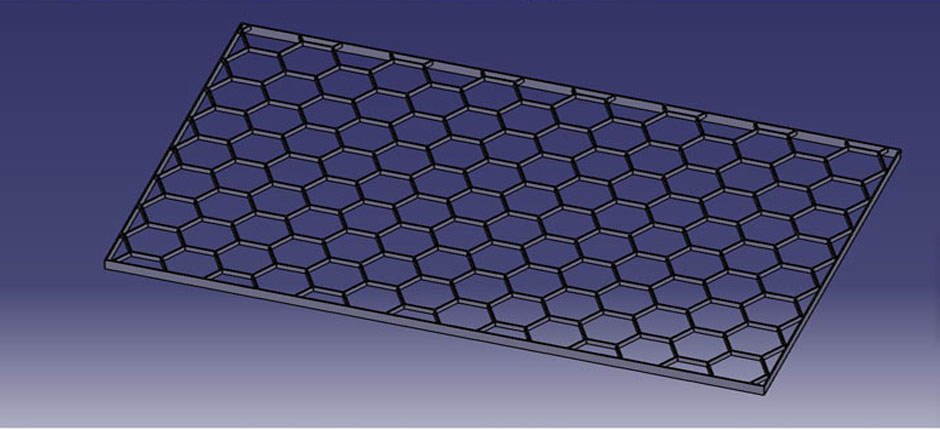

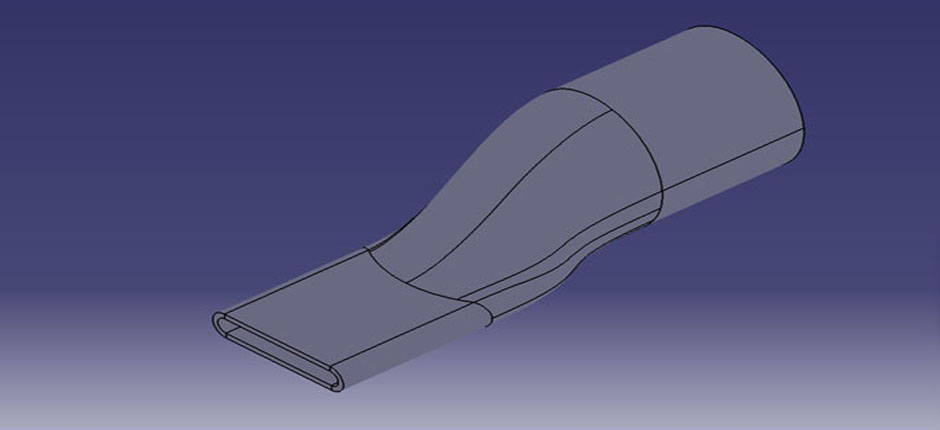

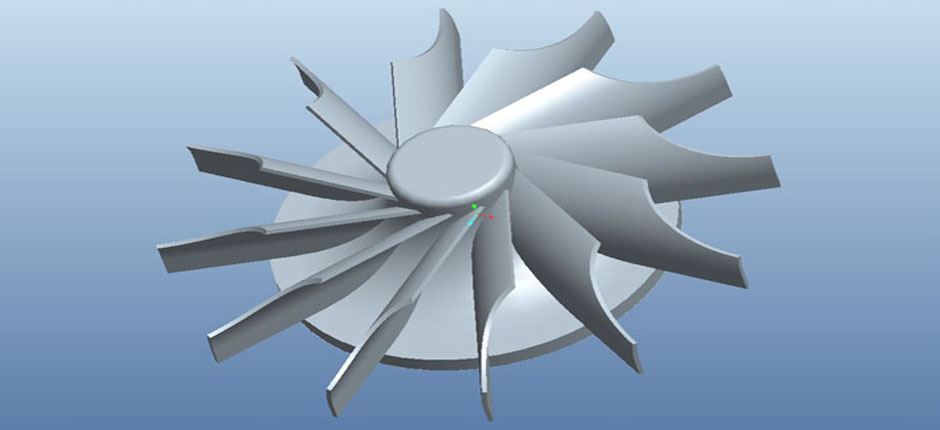

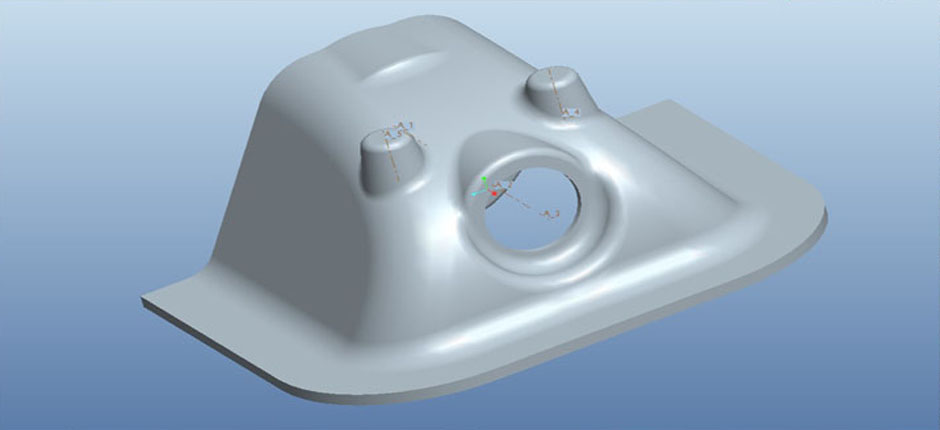

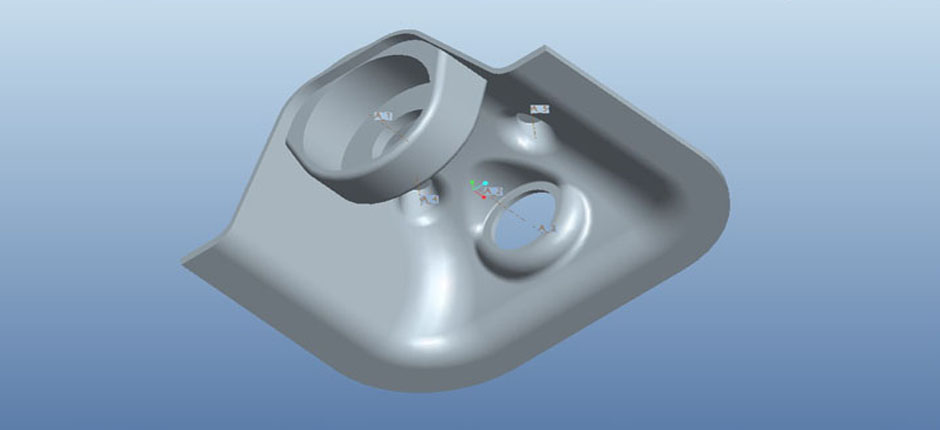

This can be simple 2D drawing / drafting or 3D parametric feature based solid/surface modeling. Such software includes

technology such as Hybrid Modeling, Reverse En-gineering, KBE (knowledge-based engineering), NDT (Nondestructive testing),

and Assembly con-struction.

This step covers many engineering disciplines including: mechanical, electrical, electronic, software (embedded),

and domain-specific, such as architectural, aerospace, automotive, ... Along with the actual creation of geometry

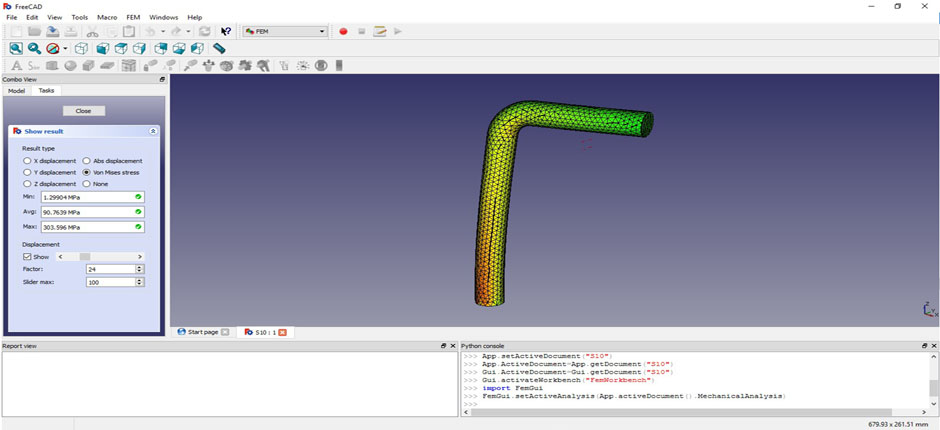

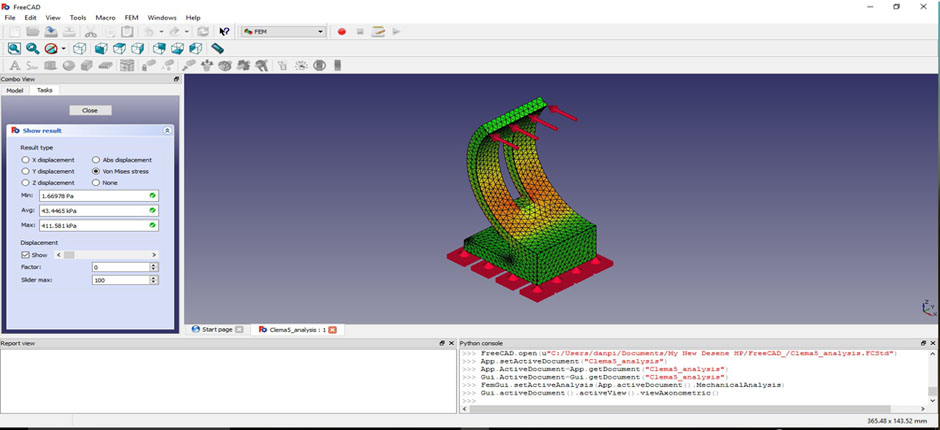

there is the analysis of the components and product assemblies. Simulation, validation and optimization tasks are

carried out using CAE (computer-aided engineering) software either integrated in the CAD package or stand-alone.

These are used to perform tasks such as:- Stress analysis, FEA (finite element analysis); kinematics; computational fluid

dynamics (CFD); and mechanical event simulation (MES). CAQ (computer-aided quality) is used for tasks such as

Dimensional tolerance (engineering) analysis. Another task performed at this stage is the sourcing of bought out

components, possibly with the aid of procurement systems.

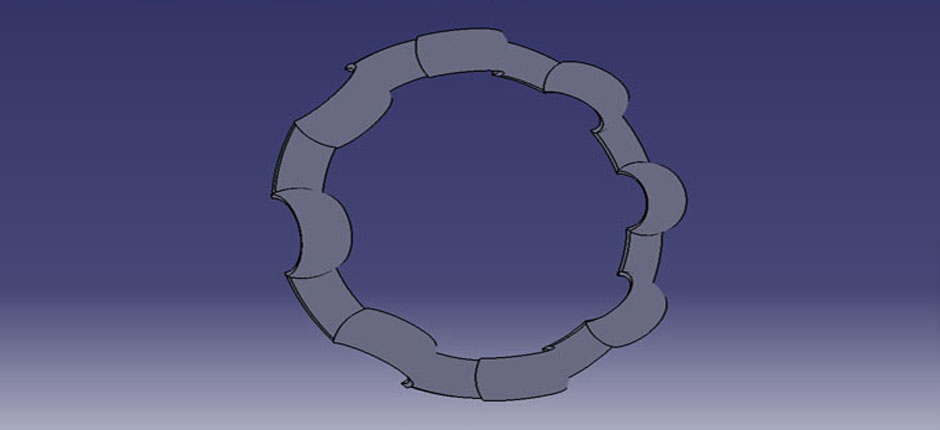

Realize

Manufacture, make, build, procure, produce, sell and deliver

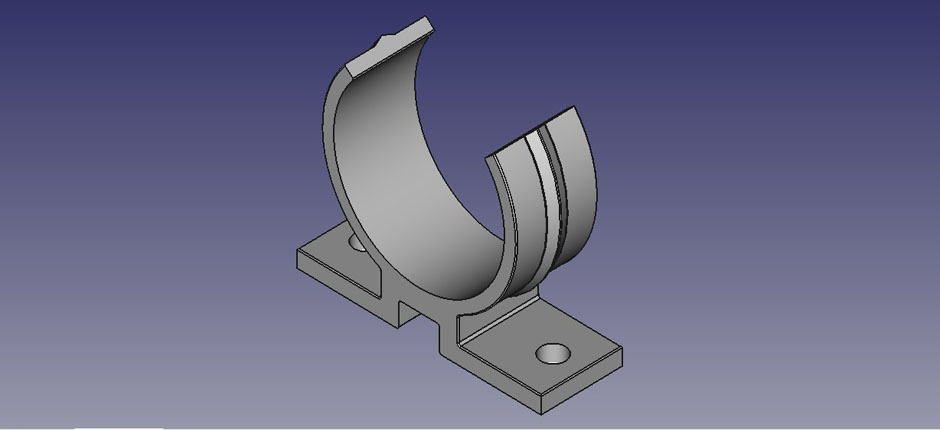

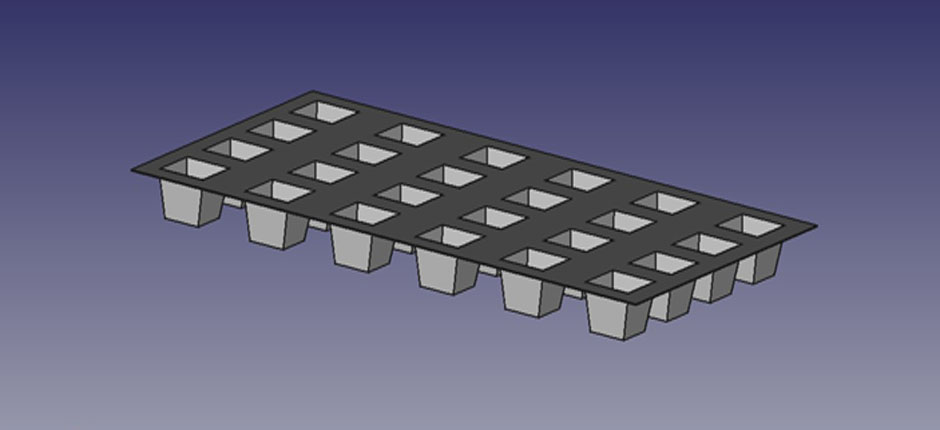

Once the design of the product’s components is complete the method of manufacturing is defined. This includes CAD

tasks such as tool design; creation of CNC Machining instructions for the prod-uct’s parts as well as tools to manufacture

those parts, using integrated or separate CAM computer-aided manufacturing software. This will also involve analysis tools

for process simulation for opera-tions such as casting, molding, and die press forming. Once the manufacturing method

has been identified CPM comes into play. This involves CAPE (computer-aided production engineering) or

CAP/CAPP – (production planning) tools for carrying out factory, plant and facility layout and production simulation.

For example: press-line simulation; and industrial ergonomics; as well as tool selection management. Once components are

manufactured their geometrical form and size can be checked against the original CAD data with the use of computer-aided

inspection equipment and software. Parallel to the engineering tasks, sales product configuration and marketing documentation

work take place. This could include transferring engineering data (geometry and part list data) to a web based sales

configurator and other desktop publishing systems.

All phases: product lifecycle

Communicate, manage and collaborate

None of the above phases can be seen in isolation. In reality a project does not run sequentially or in isolation of other

product development projects. Information is flowing between different people and systems. A major part of PLM is the

co-ordination and management of product definition data. This includes managing engineering changes and release status

of components; configuration prod-uct variations; document management; planning project resources and timescale and risk

assessment.

For these tasks graphical, text and metadata such as product bills of materials (BOMs) needs to be managed.

At the engineering departments level this is the domain of PDM – (product data man-agement) software, at the corporate

level EDM (enterprise data management) software, these two definitions tend to blur however but it is typical to see two

or more data management systems with-in an organization. These systems are also linked to other corporate systems such as SCM,

CRM, and ERP. Associated with these system are project management Systems for project/program plan-ning.

This central role is covered by numerous collaborative product development tools which run throughout the whole lifecycle

and across organizations. This requires many technology tools in the areas of conferencing, data sharing and data translation.

The field being product visualization which includes technologies such as DMU (digital mock-up), immersive virtual digital

prototyping (virtual reality), and photo-realistic imaging.

User skills

The broad array of solutions that make up the tools used within a PLM solution-set (e.g., CAD, CAM, CAx...) were initially

used by dedicated practitioners who invested time and effort to gain the required skills. Designers and engineers worked

wonders with CAD systems, manufacturing engineers became highly skilled CAM users while analysts, administrators and managers

fully mastered their support technologies. However, achieving the full advantages of PLM requires the participation of many people

of various skills from throughout an extended enterprise, each requiring the ability to access and operate on the inputs and

output of other participants.

Despite the increased ease of use of PLM tools, cross-training all personnel on the entire PLM tool-set has not proven

to be practical. Now, however, advances are being made to address ease of use for all participants within the PLM arena.

One such advance is the availability of "role" specific user interfaces. Through tailorable user interfaces (UIs), the commands

that are presented to users are appropriate to their function and expertise.

These techniques include:

- Concurrent engineering workflow

- Industrial design

- Bottom–up design

- Top–down design

- Both-ends-against-the-middle design

- Front-loading design workflow

- Design in context

- Modular design

- NPD new product development

- DFSS design for Six Sigma

- DFMA design for manufacture / assembly

- Digital simulation engineering

- Requirement-driven design

- Specification-managed validation

- Configuration management